Our specific solution

Instead of offering a standard product, we entered into a close co-engineering partnership with their global R&D team. Together, we explored the problem from multiple angles, iterating through several design concepts using rapid prototyping technologies. Each concept was validated through advanced CFD simulations and empirical testing, ensuring the final design would meet both performance and integration requirements.

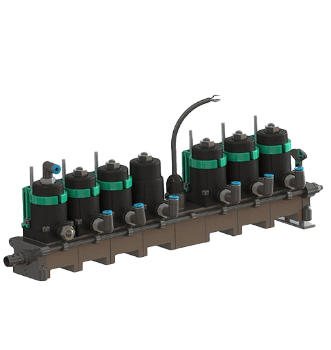

The result was a precision pulse dosing valve, built on proven solenoid technology and enhanced with a miniature pressure sensor. This sensor enabled real-time feedback and control, significantly improving dosing accuracy and repeatability. The valve was designed as part of an integrated system, seamlessly embedded into the customer's main control circuit board, streamlining the architecture and improving overall system efficiency.

- f --001.jpg)