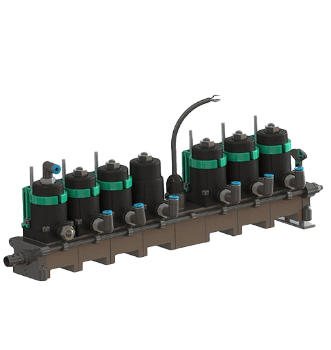

Our partner develops robotic systems that perform an automatic Cleaning in Place (CIP) cycle three times a day. Initially, this cleaning process relied on individual valves that had to be interconnected. This setup posed significant challenges: it required a lot of space, was costly, and lacked modularity for different system configurations.