- j --005-edit.jpg)

Mechatronic solutions for smarter systems

We combine deep expertise in valve technology, electronics and valve control to develop custom mechatronic solutions that solve real-world engineering challenges. Whether it’s integrating NB-IoT connectivity for smart irrigation, implementing valve switch detection in high-frequency valve applications to reduce power consumption and increase switching accuracy, or combining pressure sensing and control electronics to create constant flow regulators: we bring together disciplines to simplify complexity.

Every solution starts with understanding your application. No catalogs.

We invest in partnerships growing and evolving alongside your business!

Our solutions deliver consistent, reliable performances.

We combine electronics, mechanics and software to solve complex challenges.

Technology for control and simplified precision

Our strength lies in co-creating intelligent, compact and reliable systems that help our customers innovate with confidence.

The constant flow regulator (CFR) is a real world example of one of our custom mechatronic solutions, designed to deliver consistent flow or pressure in demanding environments, without the complexity or cost of traditional mass flow controllers. Developed for design engineers in medical and analytical device industries, the CFR offers a streamlined solution that combines high performance with ease of integration.

How it works

At its core, the CFR merges a precision proportional valve, a high accuracy pressure sensor, custom control electronics and an advanced control algorithm. This synergy enables stable flow regulation across varying conditions, while maintaining the accuracy and responsiveness expected from far more elaborate systems.

Built for OEM integration

By simplifying the control architecture, the CFR reduces system complexity and cost, while enhancing reliability. Its compact design and integrated functionality make it ideal for OEMs seeking to optimize space, performance and interface simplicity.

- h --004.jpg)

Proven in practice

One proven application is in dental laser surgery systems, where the CFR precisely regulates gas flow. To ensure optimal integration we joint our customers engineering team, to optimize our customers system performance by customizing our design. This integration has led to measurable improvements in system accuracy and reliability, helping manufacturers meet stringent performance standards without overengineering.

Engineering solutions together

The CFR reflects Gevasol’s commitment to co-creating solutions that solve real-world engineering challenges. Together we build mechatronic solutions that go Beyond Standard offerings, delivering smarter, more reliable ways to control flow in your systems.

By combining skill, creativity and a deep sense of collaboration, Gevasol enables its customers to thrive in their respective fields. It is not about being the best, but about making others the best. Through long-term partnerships built on trust, a commitment to solving complex problems, and a focus on real-world impact, Gevasol continues to shape industries through fluid control solutions that matter.

What did we achieve recently and how dit we co-create these unique solutions? Read more about it!

At Gevasol, we believe that meaningful innovation starts with listening. When a Tier 1 aviation equipment supplier approached us with a challenge in their oxygen safety systems, we began by understanding their needs in depth. Their existing valve solutions lacked the precision required for accurate gas bolus delivery, and each new configuration demanded custom adaptors; adding complexity, cost, and limiting scalability.

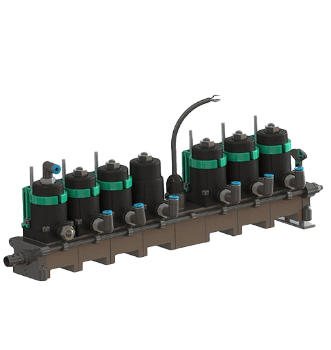

Our partner develops robotic systems that perform an automatic Cleaning in Place (CIP) cycle three times a day. Initially, this cleaning process relied on individual valves that had to be interconnected. This setup posed significant challenges: it required a lot of space, was costly, and lacked modularity for different system configurations.

Share your question with us: we'll collaborate with you to find the right solution.