Deep understanding, real impact

Dairy solutionsAt Gevasol we develop fluid control solutions that help make dairy robotics smarter and more reliable. Our expertise in this field comes from years of close collaboration with the market leader. This partnership gives us a deep insight into the specific needs of this industry. All our dairy robotics activities are carried out exclusively for this customer. This allows us to fully focus on delivering maximum added value. Not just in technology, but in trust, responsiveness and long-term reliability!

We help our long-term partners to be the best.

We co-create and work with top engineers worldwide.

We stop if our partner is fully satisfied.

Co-creation from concept to production

We don’t just supply components, we co-create solutions. Together with our OEM partner, we develop custom systems from initial concept to full-scale production. This includes industrialization and life-cycle management, ensuring every solution is robust, scalable and tailored to real-world use.

Our development cycles are fast and flexible, shaped by continuous feedback and close interaction with our partner’s engineering and operations teams.

Gevasol delivers maximum value through technology, trust and long-term commitment.

- l --005.jpg)

Precision for demanding applications

Our portfolio includes high-precision, high-reliability control valves, hygienic design valves tailored for robotic milking systems, and mechatronic sensor-subsystems that combine fluid control with intelligent sensing.

These technologies go far beyond meeting basic dairy environment standards, they are engineered for the high-end performance that robotic milking demands. From hygiene-critical operation to precise control under dynamic conditions, our solutions support the next generation of dairy automation.

Beyond Standard: built on trust

We operate beyond standard. Our team works side by side with our OEM partner; not just as a supplier, but as part of their ecosystem. We’re involved in every stage, from early design discussions to long-term support. This close collaboration allows us to respond quickly, adapt to changing needs and deliver solutions that truly fit. It’s a way of working shaped by curiosity, commitment, and a deep sense of responsibility.

By combining skill, creativity and a deep sense of collaboration, Gevasol enables its customers to thrive in their respective fields. It is not about being the best but about making others the best. Through long-term relationships built on trust, a commitment to solving complex problems, and a focus on real-world impact, Gevasol continues to shape industries through fluid control solutions that matter.

Our solutions go Beyond Standard. Learn more about it!

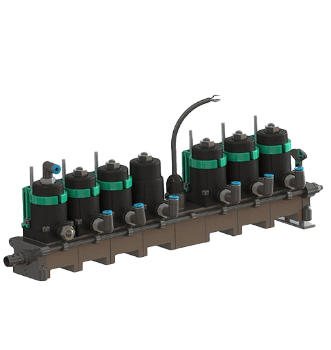

Our partner develops robotic systems that perform an automatic Cleaning in Place (CIP) cycle three times a day. Initially, this cleaning process relied on individual valves that had to be interconnected. This setup posed significant challenges: it required a lot of space, was costly, and lacked modularity for different system configurations.

At Gevasol, we believe that meaningful innovation starts with listening. When a Tier 1 aviation equipment supplier approached us with a challenge in their oxygen safety systems, we began by understanding their needs in depth. Their existing valve solutions lacked the precision required for accurate gas bolus delivery, and each new configuration demanded custom adaptors; adding complexity, cost, and limiting scalability.

Share your question with us: we'll collaborate with you to find the right solution.