Flow control for medical devices

Instead of adapting your system to fit a catalogue product, which often leads to compromises, we work side by side with your engineering team to fine-tune our valve tolerances to your exact control requirements. This collaborative approach ensures better performance and a cleaner system design. Our motivation goes beyond engineering excellence. We’re driven by the opportunity to contribute to technologies that improve lives: an ambition deeply rooted in Gevasol’s core values.

We help our partners to be the best in what they do.

We only work and create with top engineers world wide.

We deliver results until your goals are fully achieved.

Built through co-development

We work from concept to implementation, combining PhD-level engineering with hands-on experience in fluid dynamics, electronics and materials science. This integrated approach allows us to create custom solutions that go far Beyond Standard catalogue products.

For example, we developed a high-precision proportional valve for a medical ventilator OEM, specifically optimized for low-flow, high-accuracy applications. In addition, we’ve engineered several high-flow, high-pressure valves for nitric oxide dosing, where safety and control are critical. These solutions reflect our ability to meet demanding medical requirements with precision and reliability; always tailored to the needs of our partners.

Medical device companies choose Gevasol because we understand proportional valves, deeply. Our goal is to help you achieve the highest level of control and performance.

- m --001.jpg)

To give a clear explanation

We work side by side with your team to understand your system and goals. We also combine deep technical knowledge with practical experience.

We always deliver, including cleanroom-compatible manufacturing when needed. We can adapt to any existing footprint: we engineer specifically for your application. And finally: we stay involved throughout the entire product lifecycle!

A strategic partner, not just a supplier

Support is built into every stage; from early development and prototyping to production, optimization, and lifecycle management.

We stay involved to ensure your flow control solution performs reliably, evolves with your needs, and remains supported for the full lifecycle of your products.

Share your challenge with us: let’s solve it together.

By combining skill, creativity and a deep sense of collaboration, Gevasol enables its customers to thrive in their respective fields. It is not about being the best but about making others the best. Through long-term relationships built on trust, a commitment to solving complex problems, and a focus on real-world impact, Gevasol continues to shape industries through fluid control solutions that matter.

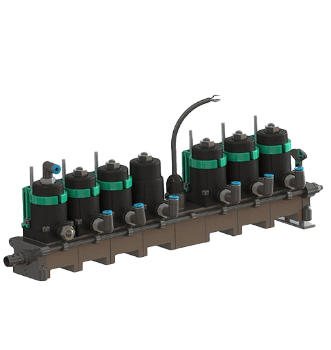

Our partner develops robotic systems that perform an automatic Cleaning in Place (CIP) cycle three times a day. Initially, this cleaning process relied on individual valves that had to be interconnected. This setup posed significant challenges: it required a lot of space, was costly, and lacked modularity for different system configurations.

At Gevasol, we believe that meaningful innovation starts with listening. When a Tier 1 aviation equipment supplier approached us with a challenge in their oxygen safety systems, we began by understanding their needs in depth. Their existing valve solutions lacked the precision required for accurate gas bolus delivery, and each new configuration demanded custom adaptors; adding complexity, cost, and limiting scalability.

Share your question with us: we'll collaborate with you to find the right solution.