Agriculture: milliseconds make a difference

Imagine spraying a weed patch just 15 centimetres wide while driving 25 kilometres per hour. That gives your system only 20 milliseconds to act. Any inaccuracy means missing the weed or hitting the crop. At Gevasol, we develop mechatronic solutions that go beyond this requirement. Our systems not only hit the target with millisecond accuracy, it even gives farmers the ability to regulate the dosage within this section. This helps farmers protect yields, reduce chemical use and contribute to a healthier food chain.

We help our partners to be the best in what they do.

We work and create with top engineers worldwide.

We deliver results until your goals are fully achieved.

Chemical diversity demands customization

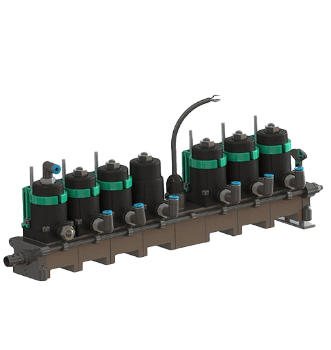

Where one substance flows like water at room temperature, another crystallizes when cold. Some crop protection agents are so aggressive they degrade standard seals within hours. Others require stainless steel to avoid trace elements that could harm crops. Our fluid control solutions are designed to handle this chemical diversity, from corrosion-resistant valves for manure injection systems to precision dosing units that distribute fungicides down to the milliliter.

Gevasol develops fluid control solutions that enable ultra-precise spraying in co-creation!

- k --002.jpg)

Regulations drive technical choices

In a sector shaped by strict regulations, staying compliant is just the starting point. Every system we develop is tailored to the customer’s platform, enabling smarter spraying, cleaner operations, and optimal control.

This co-engineering approach empowers our partners to lead in innovation and contribute to a more secure food future, not just by complying to regulation, but by setting new standards in precision and sustainability.

By combining skill, creativity and a deep sense of collaboration, Gevasol enables its customers to thrive in their respective fields. It is not about being the best but about making others the best. Through long-term relationships built on trust, a commitment to solving complex problems, and a focus on real-world impact, Gevasol continues to shape industries through fluid control solutions that matter.

Our partner develops robotic systems that perform an automatic Cleaning in Place (CIP) cycle three times a day. Initially, this cleaning process relied on individual valves that had to be interconnected. This setup posed significant challenges: it required a lot of space, was costly, and lacked modularity for different system configurations.

At Gevasol, we believe that meaningful innovation starts with listening. When a Tier 1 aviation equipment supplier approached us with a challenge in their oxygen safety systems, we began by understanding their needs in depth. Their existing valve solutions lacked the precision required for accurate gas bolus delivery, and each new configuration demanded custom adaptors; adding complexity, cost, and limiting scalability.

Share your question with us: we'll collaborate with you to find the right solution.